Driver Education Modules

This material is entirely the copyright of SCS Transport Logistics, 2025. Unauthorised usage of the material will result in prosecution.

Personal Protective Equipment

Basic PPE whilst driving, loading, unloading, returning to base MUST BE WORN at all times. Basic PPE means high visibility shirt, working shorts or pants, safety footwear or steel cap boots and the SCS HIGH VIS VEST. SCS also provides an SCS high visibility cap which you can use when unloading and loading for clearer identification. When unloading, you must use gloves. Overalls, protective eyewear, helmets and steel caps must be worn as directed on specific work sizes.

Emergency Reporting

In the event of an emergency, emergency services is the first call, then the office.

All employees, contractors, drivers and customers understand that should an accident occur, accidents and injuries must be reported and an incident report must be filled in, in compliance with National Transport Commission regulations and Qld Main Roads regulations. If an accident occurs, it can be difficult to think quickly and clearly. That is why it is important to have a checklist of things to do which could help with insurance claims. If the vehicle is not moveable after the accident, the hazard lights must be turned on. The following checklist is provided in training, in manuals and in all vehicles:

- Are you injured? How?

- Is anyone else injured? How?

- Check you are safe in the traffic around the accident site.

- Call 000 for the police even if the damage is minor.

- Call 000 if there is injury.

- Record the time, date, location of accident.

- Take photos if possible.

- Write down the other driver’s information

- Draw a diagram if possible

- Write down names of any witnesses

- Call us!

- If needed, call a tow company but ask us first.

- Make sure the vehicle is towed to the closest assessment centre for the Vehicle’s insurance company.

- Fill in an incident report on return to base.

Incidents are investigated by the management team. Vehicle or load damage is reported, investigated and referred to the insurance broker for advice on how to proceed. Claims are lodged with the appropriate insurer within the time limit required.

Personal injury is referred to Workcover Queensland, and injured workers are supported to consult the appropriate medical professional as soon as possible after the injury. Claims are lodged with the appropriate body.

In the event of a catastrophic failure of the vehicle, the drivers are instructed to stop as soon as it is safe to do so, and report to base.

In the event of the sudden insecurity of load, drivers are instructed to stop as soon as it is safe to do so, re-secure the load, and report to base. Drivers are instructed on how all loads being transported by heavy vehicles must comply with the National Load Restraint Guide.

Fatigue Management

Driver fatigue or drowsy driving is a safety hazard for the road transport industry. The main causes of fatigue are not enough sleep, driving at night (when you should be asleep) and working or being awake for a long time.

National heavy vehicle driver fatigue laws apply to fatigue-regulated heavy vehicles, which are:

- a vehicle with a Gross Vehicle Mass (GVM) of over 12t

- a combination when the total of the GVM is over 12t

- buses with a GVM over 4.5t fitted to carry more than 12 adults (including the driver)

- a truck, or a combination including a truck, with a GVM of over 12t with a machine or implement attached.

A driver must not drive a fatigue-regulated heavy vehicle on a road while impaired by fatigue. Drivers may be impaired by fatigue even when complying with work and rest limits. It is important to spot the signs of fatigue and take a break.

Body signs:

- A lack of alertness

- Inability to concentrate

- Making more mistakes than usual

- Drowsiness, falling asleep or micro-sleeps

- Difficulty keeping eyes open

- Not feeling refreshed after a sleep

- Excessive head nodding or yawning

- Blurred vision

- Mood changes

- Changes to personal health or fitness

Vehicle signs:

- Near miss or incident

- Not keeping in a single lane

- Not maintaining a constant speed

- Noises which are unusual

- Poor gear changes

Period of continuous driving | Maximum work time | Minimum rest time |

5.5 hours | 5.25 hours | 15 continuous minutes |

8 hours | 7.5 hours | 30 minutes rests in blocks of 15 minutes |

11 hours | 10 hours | 60 minutes rests in blocks of 15 minutes |

>12 continuous hours (not including breaks as per above) | 12 hours | 6 hours sleep and rest |

Basic Tips on Safe Carriage

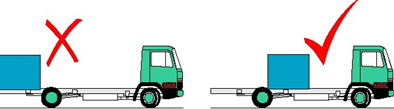

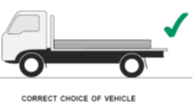

Choose a Suitable Vehicle - The vehicle must be suitable for the type and size of load.

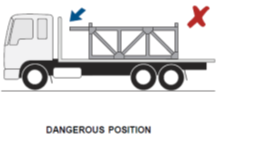

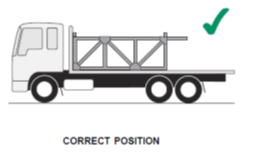

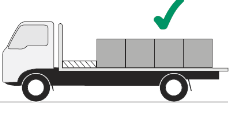

Position the Load Correctly - The load must be correctly positioned on the vehicle.

Use Suitable Restraint Equipment - The load restraint equipment and the vehicle body and attachments must be strong. enough for each type of load carried and must be in good working condition.

Provide Adequate Load Restraint - Every load must be restrained to prevent unacceptable movement during all expected conditions of operation.

Position the Load Correctly - The load must be correctly positioned on the vehicle.

Use Suitable Restraint Equipment - The load restraint equipment and the vehicle body and attachments must be strong. enough for each type of load carried and must be in good working condition.

Provide Adequate Load Restraint - Every load must be restrained to prevent unacceptable movement during all expected conditions of operation.

Sun Safety

Avoiding overexposure to ultra violet radiation (UVR) is the best way to prevent skin cancer. Follow these simple steps:

- Minimize time in the sun between 10.00 am and 3.00 pm;

- Slip on clothing;

- Slop on SPF 30+ water resistant sunscreen every 2 hours;

- Slap on a hat;

- Seek shade;

- Slide on sunglasses.

Fire Safety

Fire safety is key around engines, carrying dangerous goods, during severe summer weather, and more. Should a fire break out in the load or the cabin, fire extinguishers are available on all trucks. Do not try to control a fire. Please call emergency services and then call the office.

Risk management - SCS

National Heavy Vehicle Work Diary Usage

Most drivers of a fatigue-regulated heavy vehicle are required by law to create a record of time spent working (including driving time) and resting on a daily basis. Drivers are not allowed to drive or work more than the maximum work hours or rest less than the minimum rest hours in a certain period set out by law. All drivers of fatigue regulated heavy vehicles who drive 100km or more from their home base must carry and complete a work diary to record their work and rest times. If you have a work diary exemption notice or permit you must carry it in lieu of the work diary. In addition to the general duty to not drive a fatigue-regulated heavy vehicle on a road while fatigued, drivers must comply with certain maximum work and minimum rest limits. Standard hours are the work and rest hours allowed in the HVNL for all drivers who are not operating under National Heavy Vehicle Accreditation Scheme (NHVAS) accreditation or an exemption. They are the maximum amount of work and minimum amount of rest possible that can be performed safely without additional safety countermeasures.Counting time

Most drivers of a fatigue-regulated heavy vehicle are required by law to create a record of time spent working (including driving time) and resting on a daily basis. Drivers are not allowed to drive or work more than the maximum work hours or rest less than the minimum rest hours in a certain period set out by law. All drivers of fatigue regulated heavy vehicles who drive 100km or more from their home base must carry and complete a work diary to record their work and rest times. If you have a work diary exemption notice or permit you must carry it in lieu of the work diary. In addition to the general duty to not drive a fatigue-regulated heavy vehicle on a road while fatigued, drivers must comply with certain maximum work and minimum rest limits. Standard hours are the work and rest hours allowed in the HVNL for all drivers who are not operating under National Heavy Vehicle Accreditation Scheme (NHVAS) accreditation or an exemption. They are the maximum amount of work and minimum amount of rest possible that can be performed safely without additional safety countermeasures.Counting timeWork time

Work time includes all tasks to do with the operation of the fatigue-regulated heavy vehicle. Driving is obviously work time, but work time also includes tasks such as:

- loading and unloading the vehicle

- inspecting, servicing or repair work

- attending to the load or to passengers (on a bus)

- cleaning or refuelling the vehicle

- instructing or supervising another person including learning to drive a heavy vehicle, learning a new route, making deliveries etc.

- recording information or completing a document (for example your work diary).

It doesn’t matter if the tasks occur on private property or on a road or road related area, they are still classified as work.

What is rest time?

Rest time is all time that is not work time.

Rules for counting time

Time is always counted from the end of a rest break. The legislation requires that:

- time periods are always counted forward from the end of a rest break

- time periods of 24 hours or longer must be counted forward from the end of a ‘relevant major rest break.’

- Periods of less than 24 hours must be counted forward from the end of any period of rest time. This method is used to ensure compliance with short rest break requirements (e.g. standard hours solo driver offence of working more than seven hours 30 minutes in a period of eight hours).

- Periods of 24 hours must be counted forward from the end of a ‘relevant major rest break’. When applied to a 24 hour period a ‘relevant major rest break’ is the longest continuous rest break required for your hours option. You must start counting 24 hour periods from the end of that break. For example, you must start counting 24 hour periods from:

- Standard Hours solo – the end of a rest break of seven or more continuous hours

- Standard Hours two-up – the end of a rest break of five or more continuous hours

- Basic Fatigue Management (BFM) Hours solo – the end of a rest break of seven or more continuous hours (or at the end of a rest break of six continuous hours if a ‘split rest break’ has been taken)

Important notes - You must count work and rest time for the whole 24 hour period following the end of a relevant major rest break. If you take another (subsequent) relevant major rest break during that 24 hour period, it does not reset the 24 hour period and you must continue counting work time for that 24 hour period after the break. You must count all work time before and after the subsequent relevant major rest break in that 24 hour period. For example, if on a day you started working at 6am and worked:

- 5¼ hrs (6–11.15am) then took a 15-minute break

- 2¼ hrs (11.30am–1.45pm) and took a 90-minute break

- 4½ hrs (3.15–7.45pm) then took a seven-hour major rest break.

- You have completed the maximum 12 hours work time in any 24 hour period at 7.45pm and may not commence working again until 6am on the next day because that is when the 24 hour period you are counting finishes.

Rules for recording time in different time zones

The legislation requires that all periods of time (work time and rest time) must be counted in 15 minute blocks relative to the time zone of your base. So, for example, if you are based in Queensland and you drive into NSW during daylight savings time, you record your work and rest hours in Queensland time.

Securing the Load

The core message: “The security of your load, your life and the life of others relies on proper load restraint.” We recognize that the HVNL imposes obligations on parties in the CoR to take all reasonable steps to ensure that a driver does not commit a loading offence. We fully understand that loads carried on or in a heavy vehicle must be properly restrained so that they do not fall or dislodge.

Securing the load

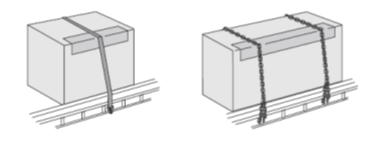

Strapping can be steel or plastic material and is used for unitising loads into packs or bundles. Strapping can be highly pre-tensioned using manual or powered tensioners, making it very suitable as a tie-down lashing for heavy objects especially on container flats and pallets. Webbing straps are tensioned using either attached clip-on, sliding winches or in-line tensioners. Geared winches are also available. Webbing straps should not be attached to tie rails by knots. Hand ratchets and end fittings should not press against the coaming rail or the load because they might distort or bend.

Chains and dogs

Chains can also be highly tensioned using turnbuckles or over-centre tensioners (also called ‘dogs’). When a fixed lever dog is released, the handle can rotate out of control releasing all the energy in the chain. If a cheater bar is used, it can be thrown off at high speed. The pivoting lever dog is designed to reduce the ‘kickback’ by limiting the lever movement. Corner protectors, sleeves or other packing material should be used where lashings and loads contact each other. Webbing straps and ropes can be easily cut on sharp edges. Sharp edges and rough surfaces prevent the lashing tension from equalising on both sides of the load. Smooth rounded corner protectors enable high tension on both sides of the load thereby increasing load restraint.

Ropes and knots

Ropes are attached to the tie rails and tensioned using knots. To be effective, the right knot must be used and correctly tied. When tensioning a rope using a ‘truckies’ hitch, avoid injury by ensuring the rope does not break or cut on a sharp object or a knot does not slip and undo. After a rope is tightened, the initial tension will usually relax after a very short time and the rope will need re-tightening.

Load shift

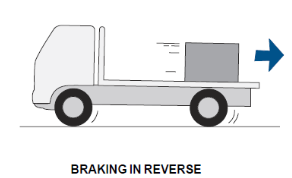

When moving, a vehicle and its load are subjected to forces caused by changes of speed, direction or slope. These forces result from braking, accelerating, cornering or travelling over cambered, undulating or uneven road surfaces and air flow. The load can shift forward when driving forward and braking or accelerating in reverse.

The load can shift rearwards when braking in reverse or accelerating forward. The braking force on the load is often higher at low speed than at high speed because the brakes may grab suddenly.

The load can shift rearwards when braking in reverse or accelerating forward. The braking force on the load is often higher at low speed than at high speed because the brakes may grab suddenly. The load can shift sideways when cornering or as the camber changes. The amount of force needed to prevent the load shifting will increase as the speed increases and as the corner gets tighter.

The load can shift sideways when cornering or as the camber changes. The amount of force needed to prevent the load shifting will increase as the speed increases and as the corner gets tighter. The force on the load when travelling over undulating or hilly roads will increase as the slope of the road increases.

The force on the load when travelling over undulating or hilly roads will increase as the slope of the road increases. When a vehicle is travelling at high speed or in windy conditions, the force caused by air flow can shift a load, especially lightweight objects with large surface areas.

When a vehicle is travelling at high speed or in windy conditions, the force caused by air flow can shift a load, especially lightweight objects with large surface areas. When a vehicle is travelling over rough surfaces, an unsecured load can shift or fall off the vehicle.

When a vehicle is travelling over rough surfaces, an unsecured load can shift or fall off the vehicle.Tie-down or direct restraint?

Loads can be restrained by two basic methods, either indirectly or directly. Tie-down is when the load is prevented from moving by friction only. Direct restraint is when the load is prevented from moving by containing, blocking or attaching it to the vehicle. These load restraint methods are summarised below which shows restraint of forward movement of the load. These principles also apply for restraint sideways, rearwards and vertically.

General Mass & Dimension Limits

We take our obligations under the NHVR seriously on mass and dimension limitations. Our operations staff and drivers are inducted into the NHVR mass and dimension limits regulations. The driver is ultimately responsible for ensuring the load mass is managed before leaving a load site. Weight and mass distribution according the axle is important part of our training.

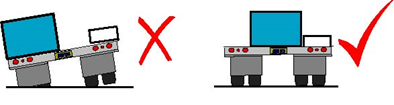

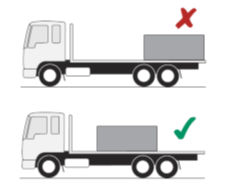

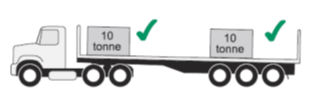

Two visual rules Here are two quick rules about mass management:

Choosing the right vehicle for the load

Correct position

The load should not project from the front, sides or rear of a vehicle because it could cause danger to other road users or damage to property.

Width, Height, Length

A load that projects beyond the rear of a vehicle by more than 1.2 metres (where Regulations permit) must be made conspicuous in daytime by fixing a brightly coloured flag or piece of material with each side at least 300mm long and at night by a red light which can be seen for 200 metres. Rear overhang limits may also apply. Make allowances for high and wide loads when driving around corners, under bridges, under electric cables, near power poles, traffic lights and other obstructions.

DO remember that the size, type and position of your load will affect the handling of your vehicle.

DO remember that loads can settle and shift during a journey, causing lashings to slacken.

DO check your load before moving off.

DO check your load every time an item is added or removed during the journey.

DO check your load periodically and at routine stops.

DO check your load after emergency braking or swerving.

DON’T take risks.

Centre of gravity – Balance and Mass Management + Axle management

Vehicles carrying liquids and loose bulk material must be designed to completely contain the load and to minimise the effect of load movement on the vehicle’s stability. The higher the position of the centre of mass of the load is above the ground, the lower the speed will be at which the vehicle will overturn when cornering (the centre of mass is also called the centre of gravity ‘C of G’). Special precautions must be taken when carrying a load with a high centre of mass. The load should be carried on a vehicle with a low platform height (e.g. drop frame trailer or low loader) or on a vehicle with good roll stability.

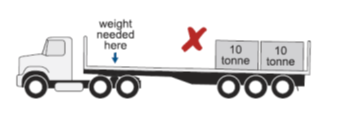

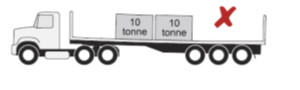

A load placed against a headboard is easier to restrain, but it can place too much weight on the steer axle and can have a high centre of mass. Heavy loads should not be carried this way. If the front axle is overloaded, the load must be placed further back for better weight distribution and arranged so its centre of mass is as low as possible.

A load should be arranged so its centre of mass is in front of the centre of the rear axle or rear axle group on utilities, trucks and trailers. This will ensure sufficient weight on steer axles to ensure safe steering and not overload the rear axle.

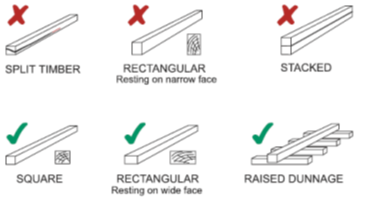

Using Dunnage

Dunnage is the packing placed under or between parts of the load. It is used to allow loading and unloading using forklifts or lifting slings. Most dunnage is made from square or rectangular hardwood or softwood timber. Some loads require inter-layer packing that prevents contact between the timber and the load and acts as a moisture barrier. Inter-layer packing includes anti-slip rubber matting bonded to the top and bottom faces of the dunnage, plastic wrapping and plastic strips. These packing materials change the amount of friction between the load and the vehicle deck and other parts of the load. The use of slippery plastic wrapping means that more tie-down lashings are required than with timber alone, whilst the use of anti-slip rubber matting usually means that fewer lashings are required. Rectangular dunnage is sometimes wrongly placed on its narrow face or stacked directly on top of itself, so that the tines of a forklift can fit under the load. This can be dangerous because the dunnage can roll under heavy braking. If the dunnage rolls, the lashings can loosen and all restraint can be lost. To prevent the dunnage from rolling, it can be placed on its wide face. Dunnage that is placed directly on the deck can be bolted to the deck or fitted with special stabilizing brackets. For heavy loads restrained by tie-down chains, it is recommended that square hardwood dunnage that is at least 63 mm thick, or softwood dunnage that is at least 100 mm thick, is used. If the height of the dunnage needs to be raised (for uneven loads) it should be stacked alternatively at right angles to keep it stable. If the dunnage spans between support points it must be strong enough to support the weight of the load, the tie-down clamping forces and the shock from bumps. If the dunnage is not strong enough, additional supports should be added or stronger dunnage used or, alternatively, the load rearranged.

Dangerous Goods

The transportation of dangerous goods is required to comply with the Australian Dangerous Goods Code (2011). This code highlights all the safety requirements and items of safety equipment which must be carried in the vehicle including emergency procedures. All SCS vehicles display the correct placards which indicate the class of dangerous goods on the vehicle. All SCS vehicles are roadworthy, comply with annual COIs, and are free of defects. Our onsite workshop provides weekly vehicle review for road regulations and standards compliance. Specific contractors are paid to undertake specific and certified DG training, and only those contractors undertake DG work. Contractors are responsible for providing approved PPE. All safety equipment including hard helmets, masks, safety glasses, portable warning devices are stowed in the cab. All SCS vehicles carry the right fire extinguishers for the vehicle size. No passengers are permitted in the cab of a vehicle transporting dangerous goods unless they are an authorised officer, or employee of the customer authorised to accompany the goods.

Container Management

The same principles of CoR, load restraint and dangerous goods transportation apply, as well as general principles of mass management. Our vehicles and trailers allocated to the transportation of shipping containers are road and transport compliant for the task/s. Our drivers are appropriately licensed and certificated in the management of shipping container transportation, and for accessing ports. Generally, we do not unpack containers but are involved in the simple relocation of containers. Our dispatch staff liaise with freight forwarders and importers/exporters in relation to collection timeslots and notifications for accessing terminals. Whilst we are not ICS equipped and rely on freight forwarders for appropriate clearance and documentation, we do however, due to our certification, access VBS or Vehicle Booking Systems via 1-Stop for time slots. However, our drivers are appropriately trained and certificated in Maritime Security, and only appropriately trained and certificated drivers with MSICs (Maritime Security Identification Cards) are permitted to transport shipping containers.

The same principles of CoR, load restraint and dangerous goods transportation apply, as well as general principles of mass management. Our vehicles and trailers allocated to the transportation of shipping containers are road and transport compliant for the task/s. Our drivers are appropriately licensed and certificated in the management of shipping container transportation, and for accessing ports. Generally, we do not unpack containers but are involved in the simple relocation of containers. Our dispatch staff liaise with freight forwarders and importers/exporters in relation to collection timeslots and notifications for accessing terminals. Whilst we are not ICS equipped and rely on freight forwarders for appropriate clearance and documentation, we do however, due to our certification, access VBS or Vehicle Booking Systems via 1-Stop for time slots. However, our drivers are appropriately trained and certificated in Maritime Security, and only appropriately trained and certificated drivers with MSICs (Maritime Security Identification Cards) are permitted to transport shipping containers.Authority to Unload

When the SCS driver deems that loading or unloading, positioning or moving the vehicle would cause damage to the vehicle, persons, products or property, the driver is trained to receive an authority to unload by the receiver before placing the goods on-site or as close as is practical to the site.

Crane Operations

All SCS drivers of vehicles fitted with hydraulic cranes are trained in the crane operation according to manufacturer and WH&S standards of compliance including stabilisers, controls, standard rigging, fittings, load type and slinging, slinging arrangements, calculating working load, using chains, and more.

- The crane operations are carried out safely without risk to them or people or property in the vicinity.

- A full view of the load whilst controlling the crane is achievable.

- There is no crane extension under overhead power lines or cables.

- All dogman signals are followed.

- Surface gradients and composition is checked for stability before extending stabilisers.

- Stabilisers are extended and locked prior to loading or unloading.

- Precision loading is made according to vehicle tray at creep speed which is 15% less full speed.

- Reports to base are immediate if there are concerns.

- Cranes, stabilisers, controls, fittings, chain tags and grades, and slings are checked monthly for compliance with Crane Industry standards.

Exclusion Zones

Truck drivers must reduce the risk of injury by standing well clear of forklifts, cranes, moving loads and load stacks. This is a visual guide for safe movement in exclusion zones.

Working at Height

A fall prevention (protective rails) or restraint system (harness) must be used if a driver or offsider is accessing the load or tray above ground level.

Unloading is to be directed from the ground by the driver or offsider once they have established a clear view of the tray/load and the offload point.

Once unloading has commenced, no one is allowed on the tray of the truck.

Supervision of crane offload must occur at all times.

Drivers are trained in the following aspects of working at height

| ||

| ||

| ||

|  | |

|  | |

| ||

Loading or unloading when the trailer/tray is on an angle poses a significant risk. Any loading or unloading with an angle greater than 5% requires extra precautions, e.g. side pins, exclusion zone on downhill side, and constant communication with the SCS office. Loading or unloading a load which may roll is a significant risk on sites with slope along the truck. Drivers and offsiders must stand uphill and or away from the direction of any load movement. Loading or unloading when the trailer/tray is on an angle poses a significant risk. Any loading or unloading with an angle greater than 5% requires extra precautions, e.g. side pins, exclusion zone on downhill side, and constant communication with the SCS office. Loading or unloading a load which may roll is a significant risk on sites with slope along the truck. Drivers and offsiders must stand uphill and or away from the direction of any load movement. | ||